Electrolyzers Working Principle

Alkaline Water Electrolyzers

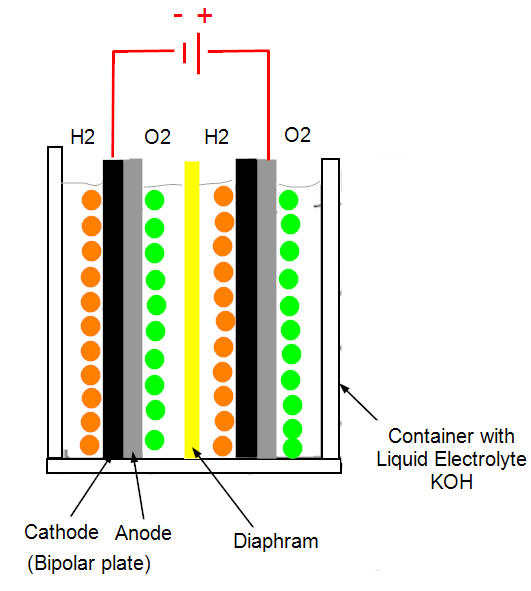

Alkaline water electrolyzers split water into the gases hydrogen and oxygen using electric energy. Splitwaters alkaline electrolysis module uses bipolar technology, consisting of a series of cells arranged side by side, forming a stack. The liquid electrolyte (KOH) is pumped through the electrolysis stack, where the product gases are formed. Hydrogen is produced at cathode and Oxygen is produced at anode. Biphasic mixtures, hydrogen or oxygen plus electrolyte, are conducted to their respective gas-electrolyte separator, responsible for water vapor and liquid electrolyte (KOH) removal.